-

Address:

19C, paik Para 3rd Row.

-

Mail us:

manmindindia@gmail.com

- GET A QUOTES

What is Industrial Automation?

Automation takes a step further mechanization that uses a particular machinery mechanism aided human operators for performing a task. Mechanization is the manual operation of a task using powered machinery that depends on human decision making.

Increase Quality and Flexibility in Your Manufacturing Process

Earlier the purpose of automation was to increase productivity (since automated systems can work 24 hours a day), and to reduce the cost associated with human operators (i.e. wages & benefits). However, today, the focus of automation has shifted to increasing quality and flexibility in a manufacturing process. In the automobile industry, the installation of pistons into the engine used to be performed manually with an error rate of 1-1.5%. Presently, this task is performed using automated machinery with an error rate of 0.00001%.

Advantages of Industrial Automation

Lower operating cost: Industrial automation eliminates healthcare costs and paid leave and holidays associated with a human operator. Further, industrial automation does not require other employee benefits such as bonuses, pension coverage etc. Above all, although it is associated with a high initial cost it saves the monthly wages of the workers which leads to substantial cost savings for the company. The maintenance cost associated with machinery used for industrial automation is less because it does not often fail. If it fails, only computer and maintenance engineers are required to repair it.

Industrial Automation

is the replacement with computers and machines to that of human thinking. The word Automation gives the meaning ‘self dictating’ or ‘a mechanism move by itself’ that derived from the Greek words Auto and Matos where auto means self while Matos means moving.

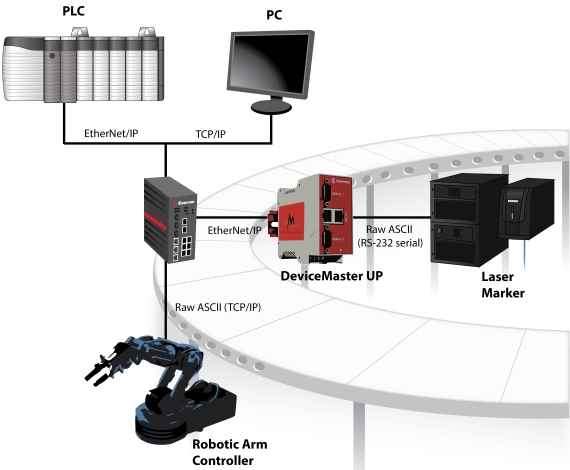

In a brief, industrial automation can be defined as the use of set technologies and automatic control devices that results the automatic operation and control of industrial processes without significant human intervention and achieving superior performance than manual control. These automation devices include PLCs, PCs, PACs, etc. and technologies include various industrial communication systems. The above figure shows the power plant automation provided by Siemens for achieving sustainable, safe and economic operations. It provides the total integrated automation (TIA) by automating every section of power plant with efficient control devices, field sensors and actuating devices. In this automation, SIMATIC modules (PLCs) are used as control devices while WinCC provides an effective graphical interface.

Advantages of Industrial Automation:

Lower operating cost: Industrial automation eliminates healthcare costs and paid leave and holidays associated with a human operator. Further, industrial automation does not require other employee benefits such as bonuses, pension coverage etc. Above all, although it is associated with a high initial cost it saves the monthly wages of the workers which leads to substantial cost savings for the company. The maintenance cost associated with machinery used for industrial automation is less because it does not often fail. If it fails, only computer and maintenance engineers are required to repair it.

-

High productivity

Although many companies hire hundreds of production workers for a up to three shifts to run the plant for the maximum number of hours, the plant still needs to be closed for maintenance and holidays. Industrial automation fulfills the aim of the company by allowing the company to run a manufacturing plant for 24 hours in a day 7 days in a week and 365 days a year. This leads to a significant improvement in the productivity of the company.

-

High Quality

Automation alleviates the error associated with a human being. Further, unlike human beings, robots do not involve any fatigue, which results in products with uniform quality manufactured at different times.

-

High flexibility

Adding a new task in the assembly line requires training with a human operator, however, robots can be programmed to do any task. This makes the manufacturing process more flexible.

-

High Information Accuracy

Adding automated data collection, can allow you to collect key production information, improve data accuracy, and reduce your data collection costs. This provides you with the facts to make the right decisions when it comes to reducing waste and improving your processes.

-

High safety

Industrial automation can make the production line safe for the employees by deploying robots to handle hazardous conditions.

WHAT IS RPA?

RPA is simple—and powerful—business process automation software. Robotic Process Automation enables you with tools to create your own software robots to automate any business process. Your "bots" are configurable software set up to perform the tasks you assign and control.

RPA bots can learn. They can also be cloned. See how they are working and adjust and scale as you see fit. It's code-free, non-disruptive, non-invasive, and easy.

RPA really is for everyone. And the benefits of RPA span all industries and business units. Applying RPA for business process automation is limited only by the imagination and putting bots to work has never been easier, with a growing marketplace of ready-made, ready-to-deploy Digital Workers available on demand, requiring no specialized IT infrastructure. Find RPA solutions already set up to take on functions such as hiring and onboarding or insurance claims processing. Put bots in, anywhere.

RPA is at the center of many organizations’ digital transformation strategies. RPA offers the ability to automate business processes quickly and easily, eliminating human intervention, and simultaneously provide a wealth of business intelligence that was never available before.

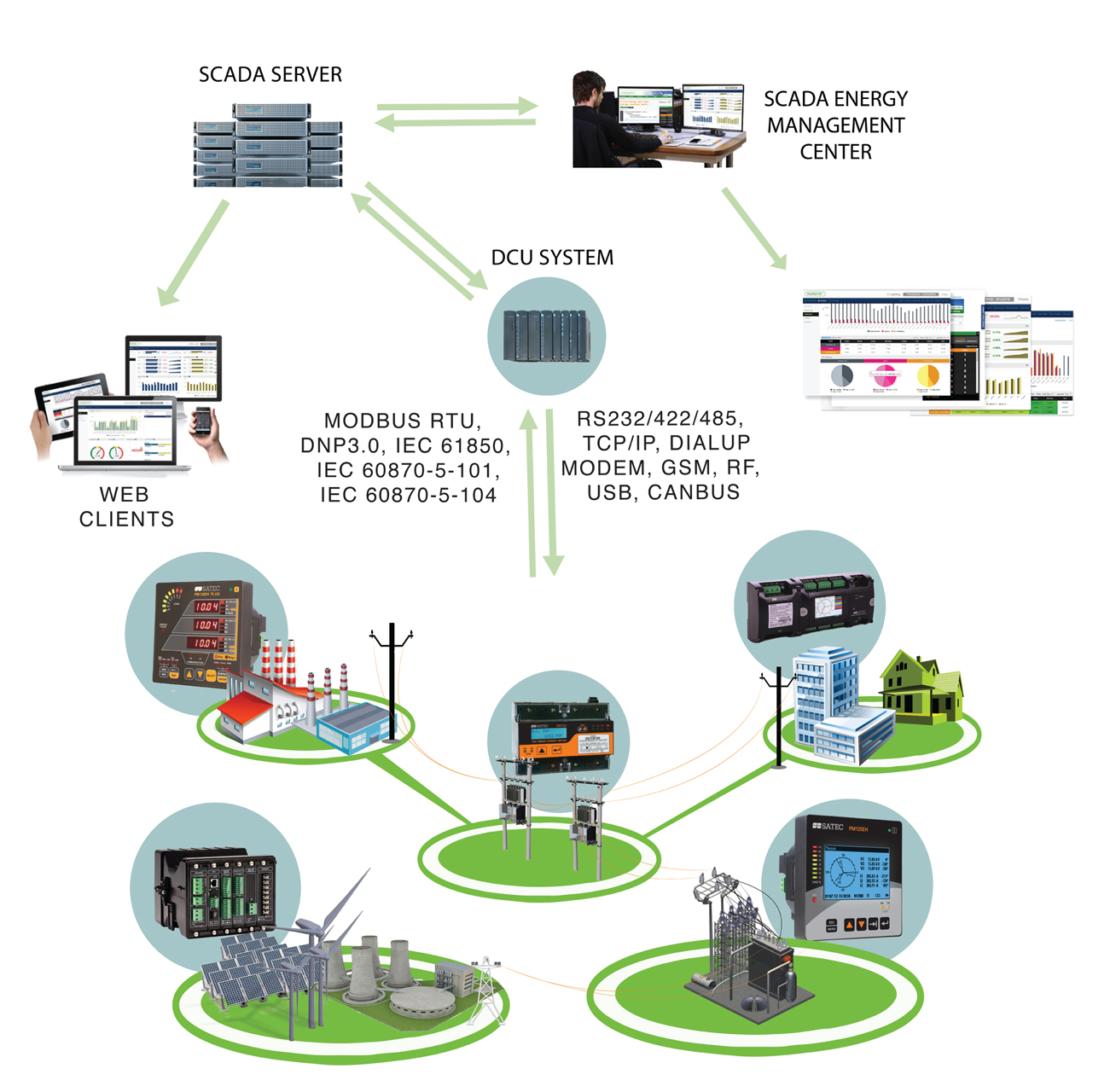

SCADA and Energy Management Solution

Our Integrated SCADA and Energy Management Solution package is a very cost-effective solution to monitor and control your application. Our Intelligent and advanced system provides complete solution for monitoring and management of energy in the industrial plants along with control and automation. All the required hardware and software for monitoring of energy are part of the system. The complete systems can be installed and configured based on user and application requirements. Multiple verticals like electric automation, process control, BMS, Fire & Safety along with Security can be integrated. Our solutions are well known for Oil & Gas, Power Transmission & Distribution, Alternative Energy Markets etc.

- Integrated SCADA with energy management system along with meters, RTU, Data concentrator, software and Data converters supply

- Display Real Time Parameters with energ

- Display trend, alarms, minimum, maximum and average values

- Options to integrate with air conditioning, water and gas meters

- Generate reports

- SMS & Email service for Alarms & Reports